About Next's Products

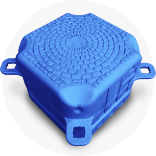

What is DeckOnCoreFloat?

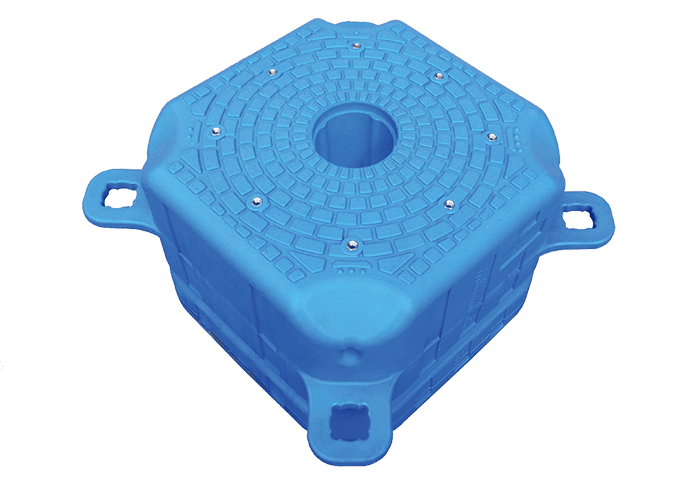

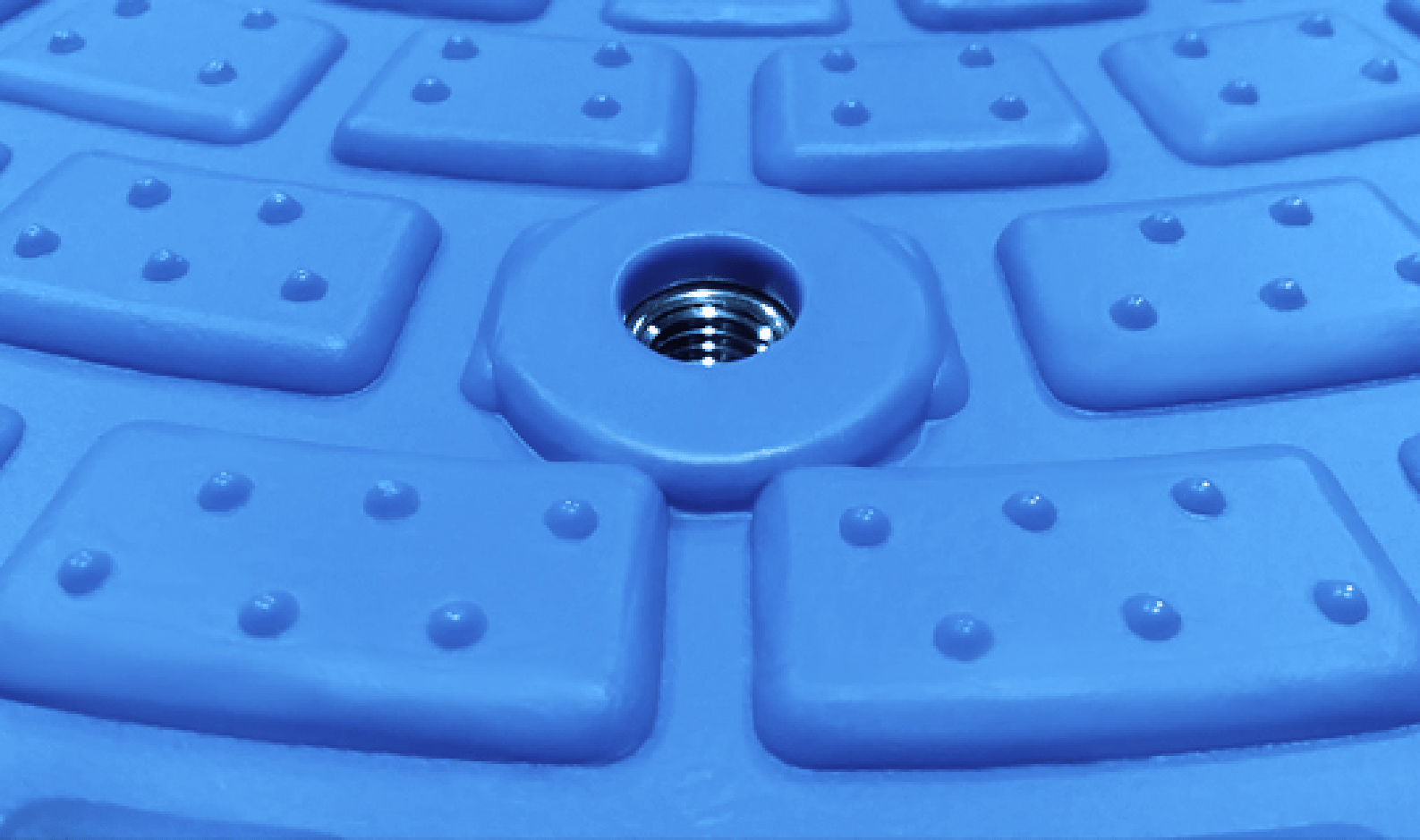

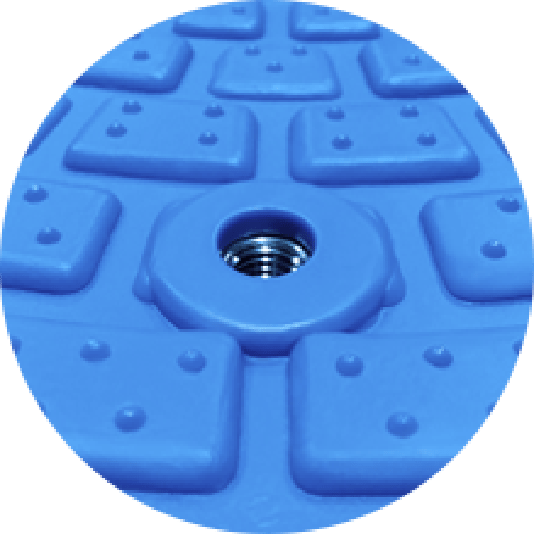

A float that combines core float's patented technology and deck-on-float's patented technology. Nuts (M10, 8 pcs. ) is inserted and molded so that decks and structures can be conveniently installed on the upper part of the float.

| Dimensions | L500MM x W500MM x H400MM |

|---|---|

| Material | High Density Polyethylene Resin (HDPE) |

| Weight | 8.5Kg (±3%) |

| Load | Approx. 91.5kgf (Approx. 366kgf/m2) |

| Freeboard | 37cm (inside and outside)+ |

| Top surface area | 0.25 m2 |

| Color | Blue (default), other colors are made to order (gray, yellow, etc.) |

| Diagonal tensile strength of the linkage | Over 18,000N The highest level in Korea |

| Nut for deck mounting | M10, 8ea |

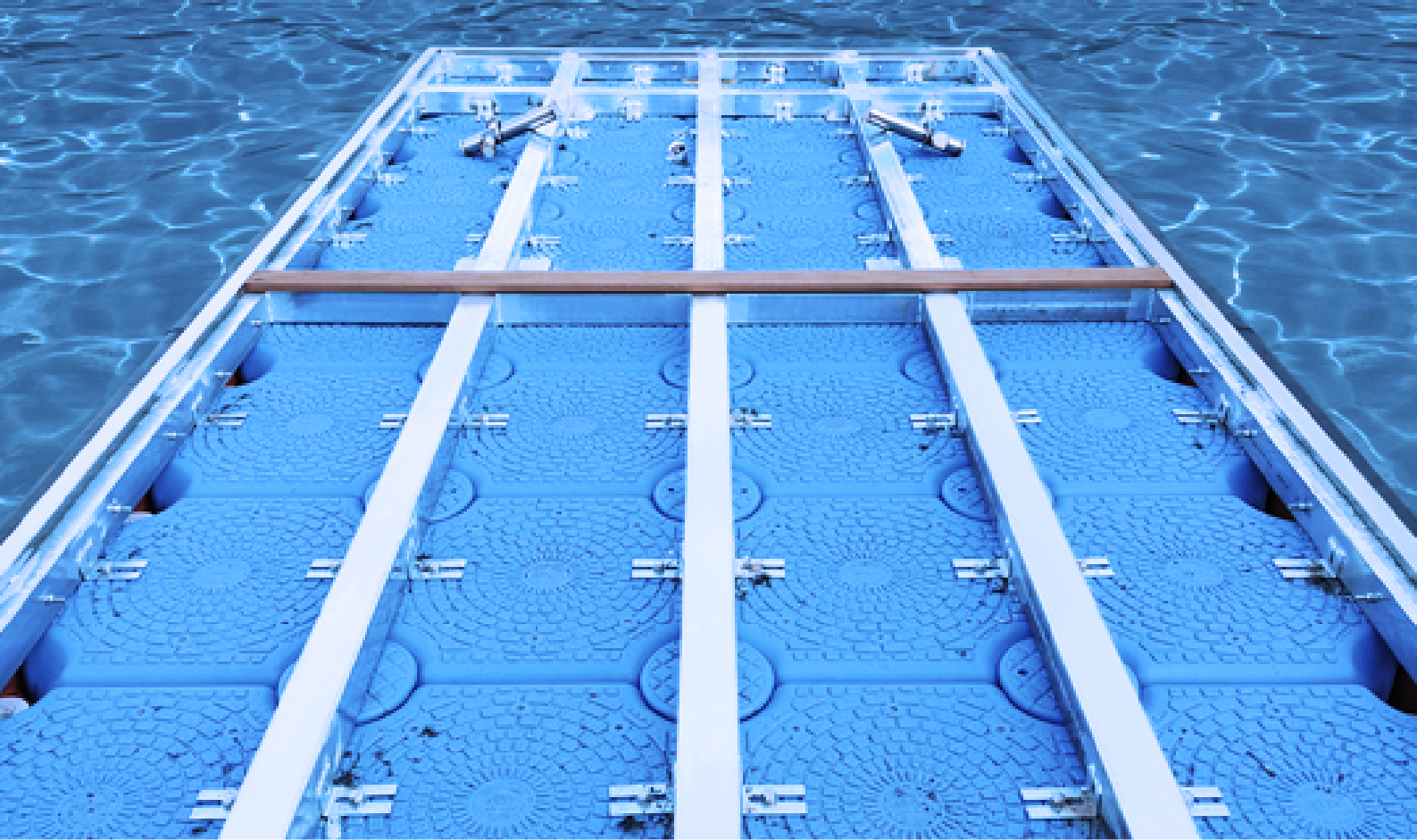

DeckOnCoreFloat Application Technology

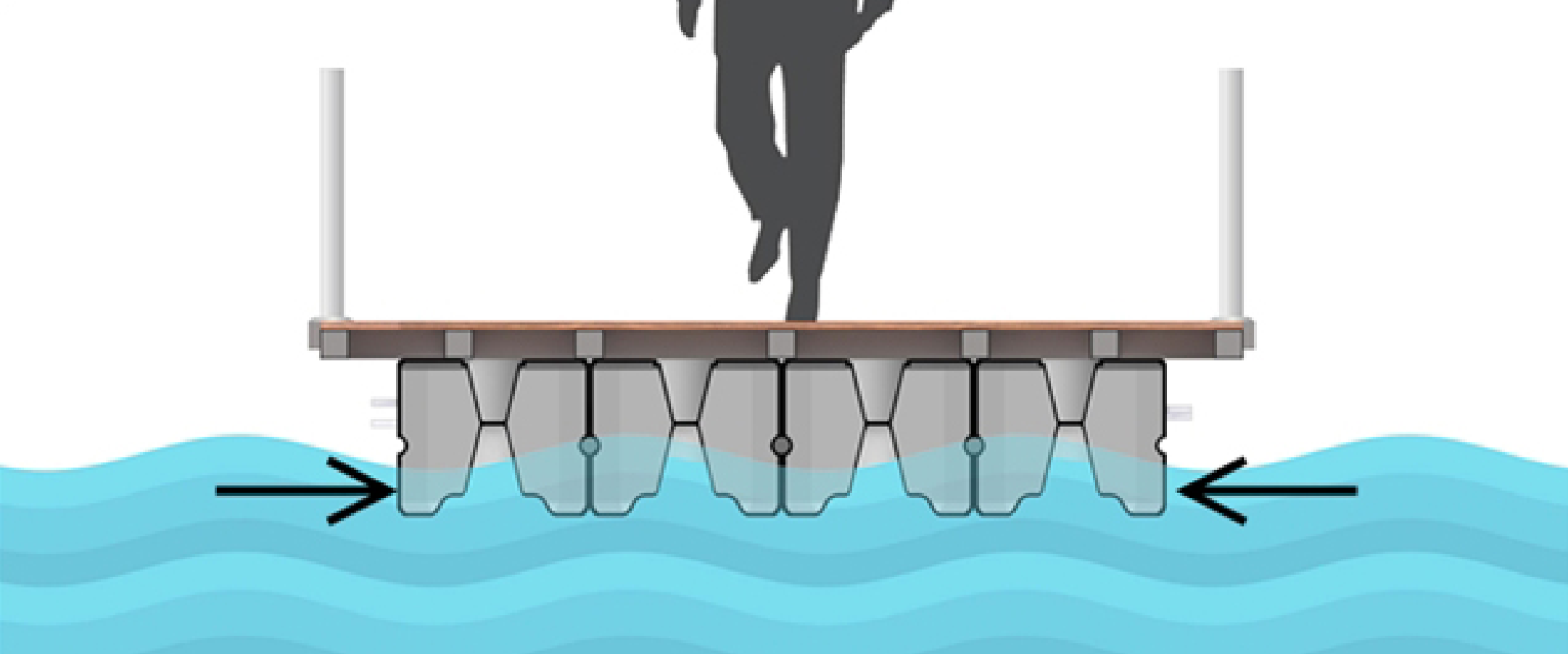

Float with floating stability

Increase water resistance by water walls

Patent No. 10-1813573

Water wall formation

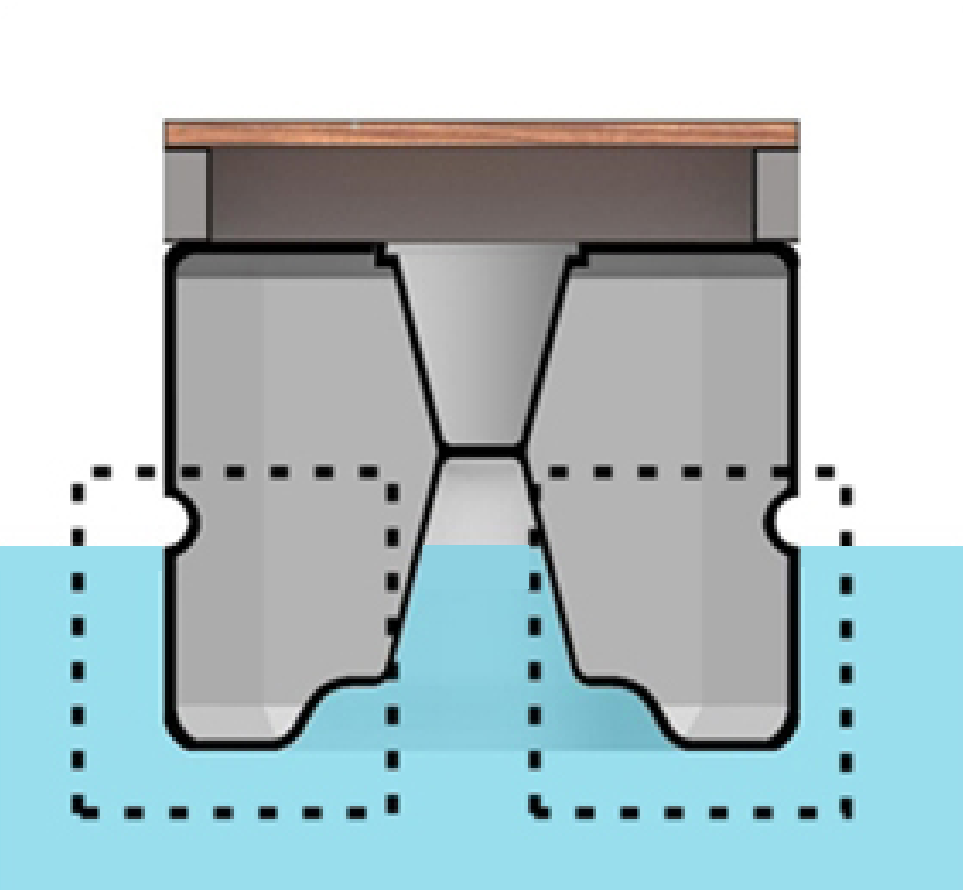

Bolt fastening structure of float

A nut that is integrally formed with the body of the float is inserted into the upper surface of the float of the float

Patent No. 10-1813572

Formed bolted structure consists of floats and finishing materials ( or structure) provides a structure that can be easily combined with a structure and made strong

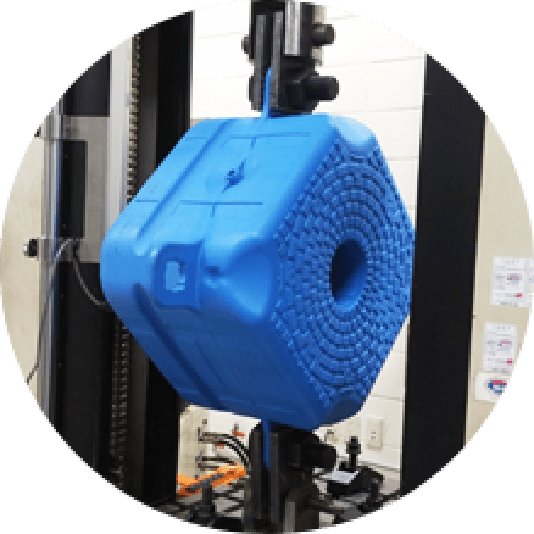

DeckOnCoreFloat quality certification

K mark performance certification (PM12018-160. prefab type) Offshore structure / 2018.09.27)

K mark performance certification (PM12018-160. prefab type) Offshore structure / 2018.09.27)

Passed most quality certification tests such as environmental hazardous substance detection test, drop impact strength test, compressive load strength test, buoyancy test, link tensile strength test, air tightness test, weather resistance test, flexural strength, chlorine spray test, etc.

The lower part of the float sinks inward, so the structure is less shaken by external forces such as swells and waves

The upper and lower surfaces are molded to be recessed inward to form a column inside the float to secure stability while walking

The nut on the upper surface of the float firmly fixes the upper structure to the float, and strong binding force against external impact

Meets the requirements of most quality certification test items

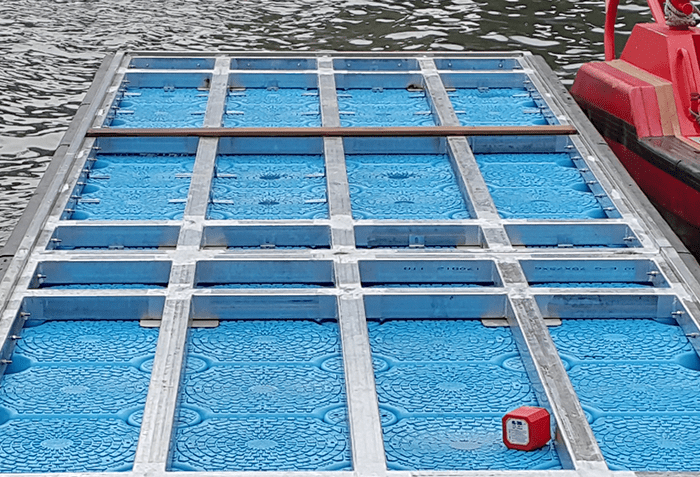

DeckOnCoreFloat Construction Order

1. Factory production of basic structures

2. Bringing floats and products to the site

3. Float water assembly

4. Combination of float and structure

5. Deck Construction

6. Oil stain painting

7. Connecting footbridge installation

8. Done

DeckOnCoreFloat Application Case

1.Consulting

1.Consulting 2.Send notice

2.Send notice 3.Assign a contact

3.Assign a contact 4.Reply to consultation

4.Reply to consultation

NEXT co., Ltd. 16-5, Oncheon-ro 165beon-gil, Paltan-myeon, Hwaseong-si, Gyeonggi-do, Republic of Korea

- Tel +82)31-447-7977

- Fax +82)31-443-7119

- Email nextfloat@next700.com

NextFloat

NextFloat CoreFloat

CoreFloat DeckOnFloat

DeckOnFloat DeckOnCoreFloat

DeckOnCoreFloat BoatSlide

BoatSlide Part

Part