About Next's Products

Our Products

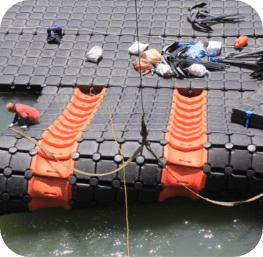

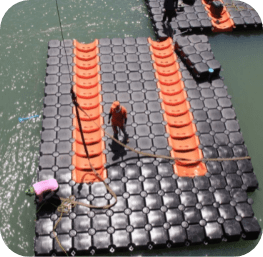

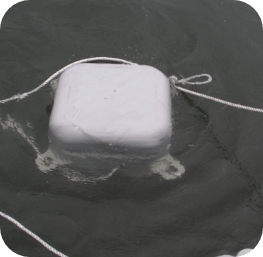

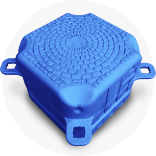

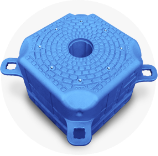

As a leader in the waterfront development industry using an eco-friendly, prefabricated floating system, Next Float is providing a variety of aquatic platforms required for eco-friendly waterfront development and marine leisure infrastructure that meet user requirements.

From the most common type of next float to deck-on floats specialized for superstructure installation, and core floats with stability on water Manufacturing various types of floats directly and exporting to the world beyond Korea.

Why should I use the products produced by Nextflot?

-

Recycled Plastics

Raw material use X -

1) Produced using S-class raw materials that meet KS standards, not cheap recycled plastic raw materials

2) Inexpensive recycled raw materials weaken the durability of the product, but S-grade raw materials can produce the best products by securing the best quality

3) The raw material of the float uses materials that meet the Korean plastic standard specifications, and various auxiliary materials are also manufactured using only standard products of excellent materials

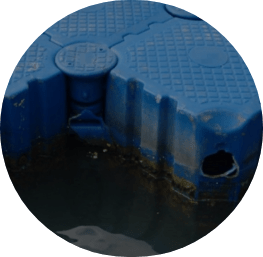

Low quality products that use recycled plastic raw materials or do not meet standards

Weak durability

Product deformation and warpage

Joint breakage

Link breakage due to low tensile strength

-

Top Quality

Pursuit -

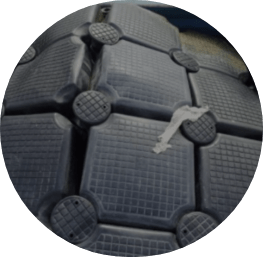

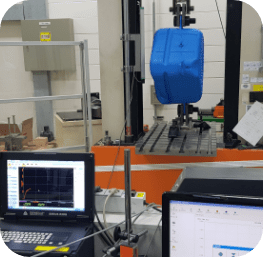

Passed the performance test of prefabricated offshore floating structures standardized by the Korea Testing Laboratory

The diagonal tensile strength of our float linkage is over 18000N, the highest in Korea

The tensile strength of the connecting ring is directly related to the durability of the entire structure due to the nature of the float used as a floating structure by being assembled in a prefabricated manner.

(In the case of low-priced products, the tensile strength of the connecting ring is less than 13000N, and some products have less than 11000N)

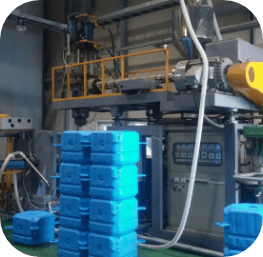

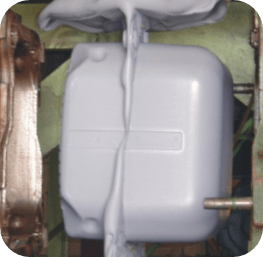

Next Float insists on blow molding

The float used as a floating structure has a lot of shocks from the outside, such as ships, so the injection molding method, which is weak against external shocks, has poor durability

Applying partial thickness control technology during the molding process to keep the thickness of the top plate 10mm different from other parts

Manufactured to maintain as much smoothness as possible on the upper surface of the float by inducing contraction and expansion due to temperature change to the lower or side surfaces of the float rather than the upper plate due to the nature of plastic products

High quality next float

Blow method molding

10mm thickness of top plate

Strong against warping

High resilience

-

Continuous R&D

and

Pursuit of quality improvement -

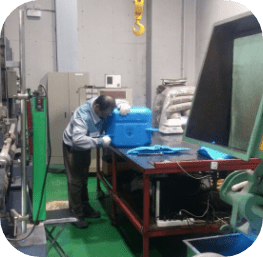

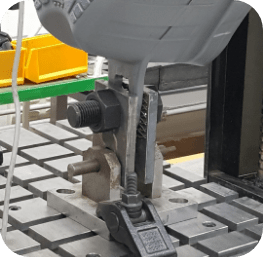

1) Continue research and development to make a more stable floating structure

2) Hosting self-construction seminar Seminar for self-construction

3) Periodic testing of finished products for quality control

Various quality improvement tests

Tensile strength test

Tensile strength test

Dumbbell buoyancy test

Buoyancy test

Request for consultation and quotation

For quick consultation, please fill out the information below and apply, and we will reply (within 24 hours on weekdays).

1.Consulting

1.Consulting 2.Send notice

2.Send notice 3.Assign a contact

3.Assign a contact 4.Reply to consultation

4.Reply to consultation

NEXT co., Ltd. 16-5, Oncheon-ro 165beon-gil, Paltan-myeon, Hwaseong-si, Gyeonggi-do, Republic of Korea

- Tel +82)31-447-7977

- Fax +82)31-443-7119

- Email nextfloat@next700.com

NextFloat

NextFloat CoreFloat

CoreFloat DeckOnFloat

DeckOnFloat DeckOnCoreFloat

DeckOnCoreFloat BoatSlide

BoatSlide Part

Part